Our reputation for designing, manufacture and delivering solutions that meet or exceeds your requirements is a result of our experienced project management, mechanical, and controls engineers as well as our skilled technicians who put it all together, install and service your equipment. Whether you need a solution for a brand-new production contract or an improvement to your existing operation, we have a wide range of experience in developing solutions that improve quality, cycle times and OEE. building efficiency and profit into your operations.

One of our customers had been experiencing heavy re-work costs on a large machined component due to deep bore and bottom plate out-of-tolerances. Turning to the Coldwater facility’s precision machining department for assistance, we assured them we could achieve higher accuracy.

Our ability to hold to stricter tolerances enabled us to deliver an improvement of about 10% over the previous method. For the customer, this resulted in a savings of nearly 20% of the total costs they had been investing.

This transport rig was manufactured by the Coldwater facility to support jet engines during transport to test rigs for performance testing. Depending upon the situation, our teams can work from a supplied design or engineer and manufacture a complete solution for precision applications.

Timely repair of turbines in the field is critical to reducing the impact of electricity outages. To reduce the repair time involved required to remove the rotor from the stator, the Coldwater team worked with a client to develop a suite of specialized, automated repair tools that was kitted and containerized. These kits eliminate the need for rotor removal, decreasing turbine downtime from weeks to days.

To produce this dryer drum, we retooled an existing line to accommodate a new dryer model and provide a more efficient operation. We replaced the existing gap expander, as well as adding a hemming and curling station. We designed the hemming operation to be performed with one pneumatic-actuated tool versus two hydraulic actuated tools featured in the original line.

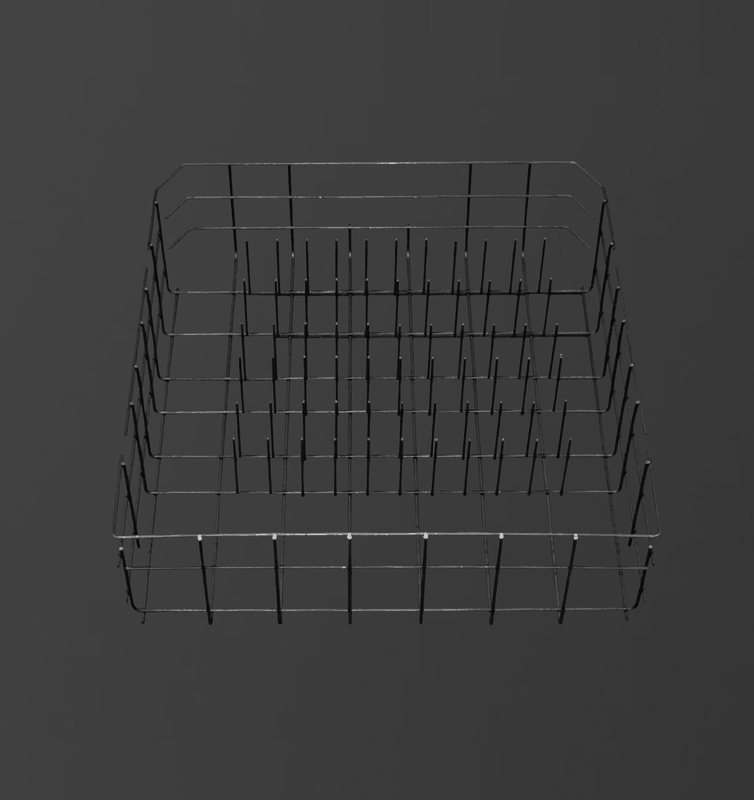

This Dishwasher Basket started life as a mere welded matt. Our solution then provided all the forming, welding and trimming needed to evolve this workpiece into a complete basket ready for coating. This automated solution utilizes no operators until the completed basket emerges from the line.

The Coldwater facility provides solutions for manufacturing a wide range of metal cabinets that include total solutions from metal blanks to finished cabinets including operations like stamping, trimming, forming, embossing, piercing, welding, wrapping, bending and hemming.

From stainless steel coil stock and flexible robotic blank handling to laser welded wrapper to finished assembly with balance rings, our Coldwater operations can provide a total solution for white good manufacturing such as laundry baskets

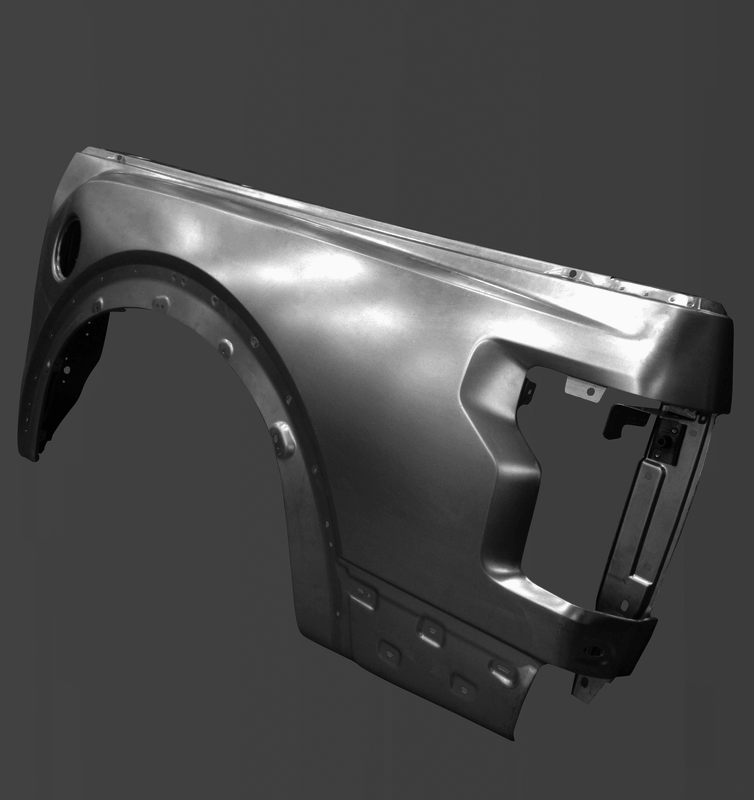

The Lincoln Electric Automation team at Coldwater provides turnkey robotic solutions for automotive body subassemblies such as hoods, tailgates, doors and truck box sides. Our solutions use the latest in robotic assembly technology and can incorporate a wide variety of joining techniques from resistance and laser welding to clinch joints, self piercing rivets and friction welded nuts and fasteners.

Our customer had a new product that required five operations – a combination of bending, sizing, crush-forming and retrimming. The initial processing approach also required additional material to accommodate the retrim prior to bending. Our solution replaced all of these operations with a single-stroke hydraulic press cycle. In addition, this approach eliminated the need for extra material.

The result? Time savings, floor space savings and an approximately 75% reduction in system cost as compared to the original processing approach.

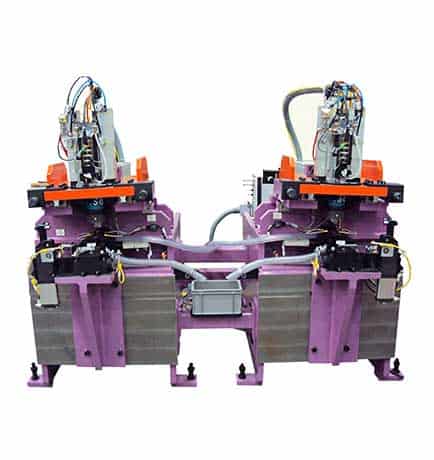

The system was designed around a servo indexing dial table and features two TOX press stations, Rofin fiber laser, Spectrum feeder, Rofin laser marking, Fanuc robot load/unload and AB controls.

To produce this Automated Transmission Gear Assembly, we designed and built an integrated cell with automatic feeding of the gear and bushing that:

1. Robotically loads the component

2. Presses the hub and gear together

3. Laser welds the components

4. Presses a wear bushing into the gear

5. Laser marks the final assembly

6. Robotically unloads the finished assembly

Our customer had been processing tubular Window Regulators using four manual cells requiring one to two operators at each cell. We developed an automated, programmable line that decoils, mills, cuts, loads and bends that was capable of processing 40 different high volume parts with approximately 250 different SKUs. Providing easy programmability for quick changeover also enabled the customer to bring low-volume parts to this line.

The result? Three of the manual stations were replaced with this single line. The customer gained through faster changeover, improved part consistency, equipment reliability and labor savings.

To produce this Transmission Torque Tube, we designed an automated processing solution consisting of four in-line presses and a transfer system. As compared to alternative single-press solutions, this line eliminated the need for a pit or the expensive rigging costs associated with larger presses. The system features a station to flip the part – top to bottom – without the typical constraints encountered when using multiple dies in one large transfer press.

Our customer was interested in replacing clinch nuts with friction welded nuts on an automotive aluminum panel. Through a series of design iterations, verified by weld lab testing, we developed an M6 nut size and nut driver that would automate pickup and welding during production.

After verifying the optimal nut design and process, we developed a two-machine solution that friction welds nuts on the same part on different ends, which enabled our customer to meet the OEM’s 11.6 second part-to-part cycle requirement.

Technical Articles

New Material Drives New Welding Processes

Welding the Unweldable, the Vapor Foil Actuator Welding Process

To produce this Expedition Truck Frame section, we provided two custom pierce stations to pierce the control arm pivot holes — post weld.

A particular challenge of this project was providing the cutting and forming of the cam washer lances from inside the bracket where there is a very limited space for tooling and supporting the mandrel.

A cylinder manufacturer was cutting down bars and tubes to size, and then manually rotating them across analog indicators to find the ‘least straight’ point on the bar. The operator would then press that bar/tube at that point to correct the deviation and manually repeat the process. This required a skilled operator, a lot of time and was not a repeatable process. Lincoln Electric Automation developed a fully automated bar/tube straightening system with embedded artificial intelligence that automatically adapts to variances in the tubes without requiring operator intervention, and is capable of handling a wide variety of lengths and diameters. This provided the company up to 60-80% decrease in cycle time while achieving desired straightness over the entire pipe.