Whether you need tooling for your production line, a precision fixture, a destacker, laser weld cell, equipment refurbishment or a turnkey automated system, Lincoln Electric Automation can deliver a solution that meets the stringent requirements of the automotive industry. Our engineers are experts in designing efficient manufacturing solutions that achieve the high accuracy and repeatability required by the OEM and Tier automotive industry while making you more efficient, productive and cost-effective.

Lincoln Electric Automation is skilled in the design and build of modular cells or turnkey automated welding and joining systems that are used in vehicle body-in-white assembly by Tier suppliers for both steel and aluminum structures. Production processes in these assembly lines incorporate a variety of material handling solutions as well as various joining technologies such as welding, hemming, adhesive bonding, clinching, riveting and more.

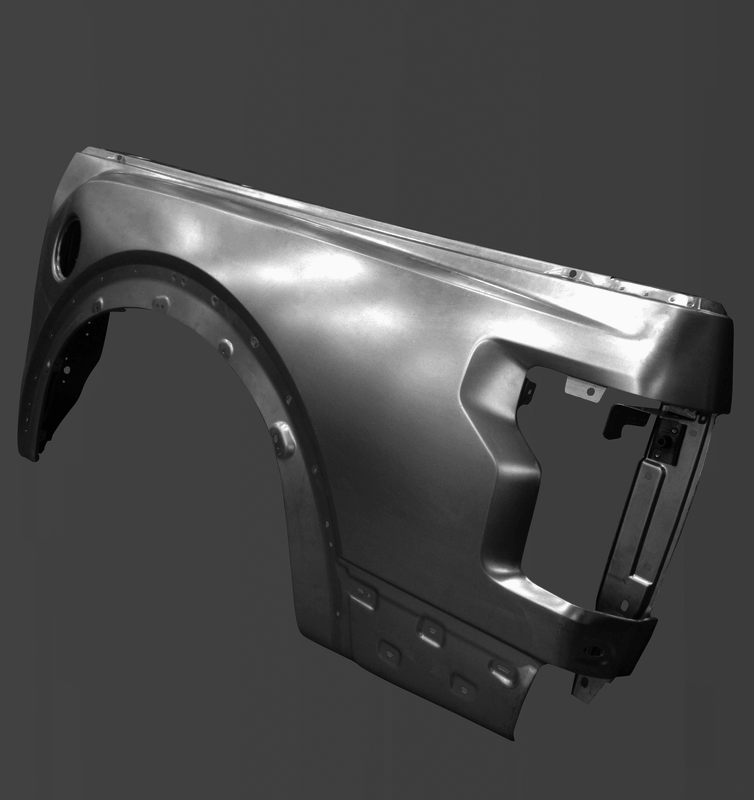

Typical applications include assembly and sub-assembly lines for closures, such as tailgates, doors, hoods, wheelhouses, roofs and structural components such as pillars, cross and front beams, reinforcements, and more.

Using laser welding module standards developed by our Lincoln Electric Automation facility, we build powertrain laser welding lines to meet each customer’s particular requirements. Our solutions include palletized transfer of components with RFID tracking through the assembly and welding process, laser ablation, robotic material handling, servo-controlled presses, laser welding and ultrasonic inspection of the weld.

When it comes to lightweighting and joining of dissimilar or mixed materials, Lincoln Electric Automation is the industry leader for new joining technologies for aluminum, magnesium and high strength materials. We are experts in both rotary friction welding and refill friction stir spot welding as well as laser welding of powertrain components.

Learn more about Spot Friction Welding Systems Here

Learn more about Component Friction Welding Here

Lincoln Electric Automation specializes in designing advanced systems that empower automotive manufacturers to boost efficiency, enhance performance, and meet stringent operational requirements. Our solutions ensure optimal pressure, flow, routing, efficiency, and storage across any vehicle architecture. We integrate cutting-edge hot plate welding technology with custom robotic load and unload processes, both upstream and downstream. Additionally, we can work with customers to design and provide custom tooling to meet unique manufacturing needs

Lincoln Electric Automation specializes in designing advanced systems that boost efficiency, enhance performance, and meet the operational needs of automotive manufacturers. Our innovative solutions help produce automotive filtration systems that protect vehicle occupants and engines while contributing to a cleaner planet.

We provide cutting-edge, efficient filtration solutions for air, oil, fuel, and coolant, ensuring the protection of engines and electrified powertrains while boosting their efficiency. Our advanced hot plate welding technology integrates effortlessly with custom robotic load and unload processes, both upstream and downstream. In addition, Lincoln Electric Automation can offer custom tooling solutions designed to meet your unique requirements.

The Lincoln Electric Automation team at Coldwater provides turnkey robotic solutions for automotive body subassemblies such as hoods, tailgates, doors and truck box sides. Our solutions use the latest in robotic assembly technology and can incorporate a wide variety of joining techniques from resistance and laser welding to clinch joints, self piercing rivets and friction welded nuts and fasteners.

Our customer had a new product that required five operations – a combination of bending, sizing, crush-forming and retrimming. The initial processing approach also required additional material to accommodate the retrim prior to bending. Our solution replaced all of these operations with a single-stroke hydraulic press cycle. In addition, this approach eliminated the need for extra material.

The result? Time savings, floor space savings and an approximately 75% reduction in system cost as compared to the original processing approach.

The system was designed around a servo indexing dial table and features two TOX press stations, Rofin fiber laser, Spectrum feeder, Rofin laser marking, Fanuc robot load/unload and AB controls.

To produce this Automated Transmission Gear Assembly, we designed and built an integrated cell with automatic feeding of the gear and bushing that:

1. Robotically loads the component

2. Presses the hub and gear together

3. Laser welds the components

4. Presses a wear bushing into the gear

5. Laser marks the final assembly

6. Robotically unloads the finished assembly

Our customer had been processing tubular Window Regulators using four manual cells requiring one to two operators at each cell. We developed an automated, programmable line that decoils, mills, cuts, loads and bends that was capable of processing 40 different high volume parts with approximately 250 different SKUs. Providing easy programmability for quick changeover also enabled the customer to bring low-volume parts to this line.

The result? Three of the manual stations were replaced with this single line. The customer gained through faster changeover, improved part consistency, equipment reliability and labor savings.

To produce this Transmission Torque Tube, we designed an automated processing solution consisting of four in-line presses and a transfer system. As compared to alternative single-press solutions, this line eliminated the need for a pit or the expensive rigging costs associated with larger presses. The system features a station to flip the part – top to bottom – without the typical constraints encountered when using multiple dies in one large transfer press.

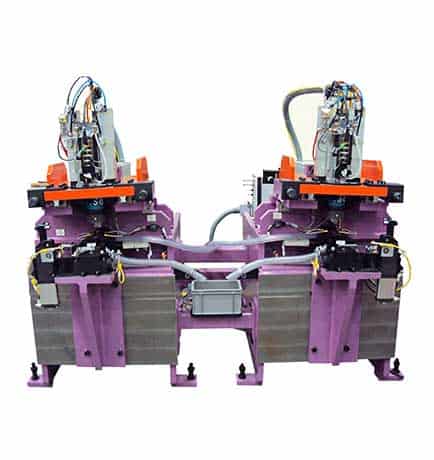

Our customer was interested in replacing clinch nuts with friction welded nuts on an automotive aluminum panel. Through a series of design iterations, verified by weld lab testing, we developed an M6 nut size and nut driver that would automate pickup and welding during production.

After verifying the optimal nut design and process, we developed a two-machine solution that friction welds nuts on the same part on different ends, which enabled our customer to meet the OEM’s 11.6 second part-to-part cycle requirement.

Technical Articles

New Material Drives New Welding Processes

Welding the Unweldable, the Vapor Foil Actuator Welding Process

To produce this Expedition Truck Frame section, we provided two custom pierce stations to pierce the control arm pivot holes — post weld.

A particular challenge of this project was providing the cutting and forming of the cam washer lances from inside the bracket where there is a very limited space for tooling and supporting the mandrel.

A manufacturer of radiator coolant recovery degas reservoir overflow expansion tanks needed a system that could operate within the constraints of the injection molding cycle and yet be automated. Processes included in the production cycle had to include mold extraction, component temperature monitoring, parametric hot plate welding, cooling, insert installation, leak testing, product marking for traceability, and bulk packaging.

The Lincoln Electric Automation team developed a fully automated cell to produce an automotive degas reservoir within the constraints of the injection molding cycle. This solution eliminates the need for operator-attended stations, reduces the amount of WIP, and reduces the footprint required for this process.

The result? 100% operator elimination and 200% production capacity improvement by optimizing utility and throughput. In addition, this customer reduced their lead time, and work in process inventory.

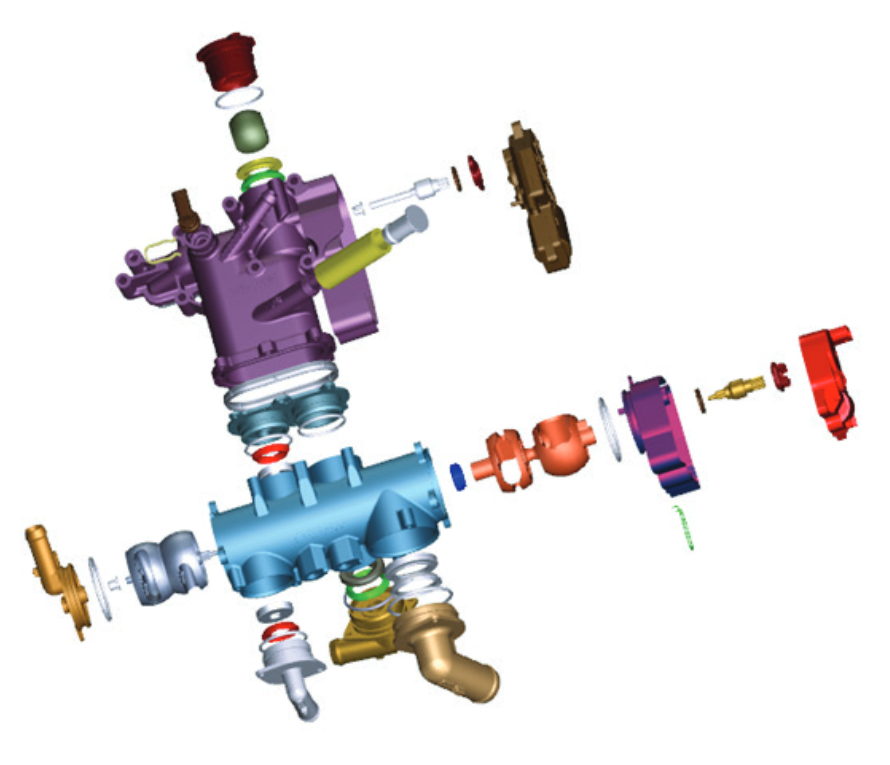

Coolant control valve manufacturers are challenged to produce complex assemblies that meet stringent performance criteria. Due to the competitive nature of the product line, it is imperative that the selected assembly process is highly efficient and cost effective.

We developed a lean cell solution to balance and optimize automation with multi-operator activity to produce a cost effective process that resulted in 28 seconds per part throughput. Features included operator staging of various components, automatic subassembly operations utilizing pick and place on process stations, robotic transfer/load/unload utilizing multi-position end of arm tooling, and buffer stations utilizing palletized conveyor systems for non-synchronous operation. Quality checks and part traceability also were incorporated into the process.

The result? 300% throughput increase and 50% operator reduction. Our solution blends user appropriate operator activity with complex automation, yields increased production rates, increases overall equipment effectiveness (OEE), and results in consistently reliable fastener torque.