Coldwater Machine is a leader in the development and manufacture of solid state welding solutions that specifically address lightweight and dissimilar materials joining, partnering with several companies to manufacture and commercialize state-of-the art welding solutions. At the same time, we have deep experience with traditional MIG and resistance welding technologies. We have designed and produced automated weld cells using fiber lasers, CO2 lasers, MIG (GMAW) and friction solutions.

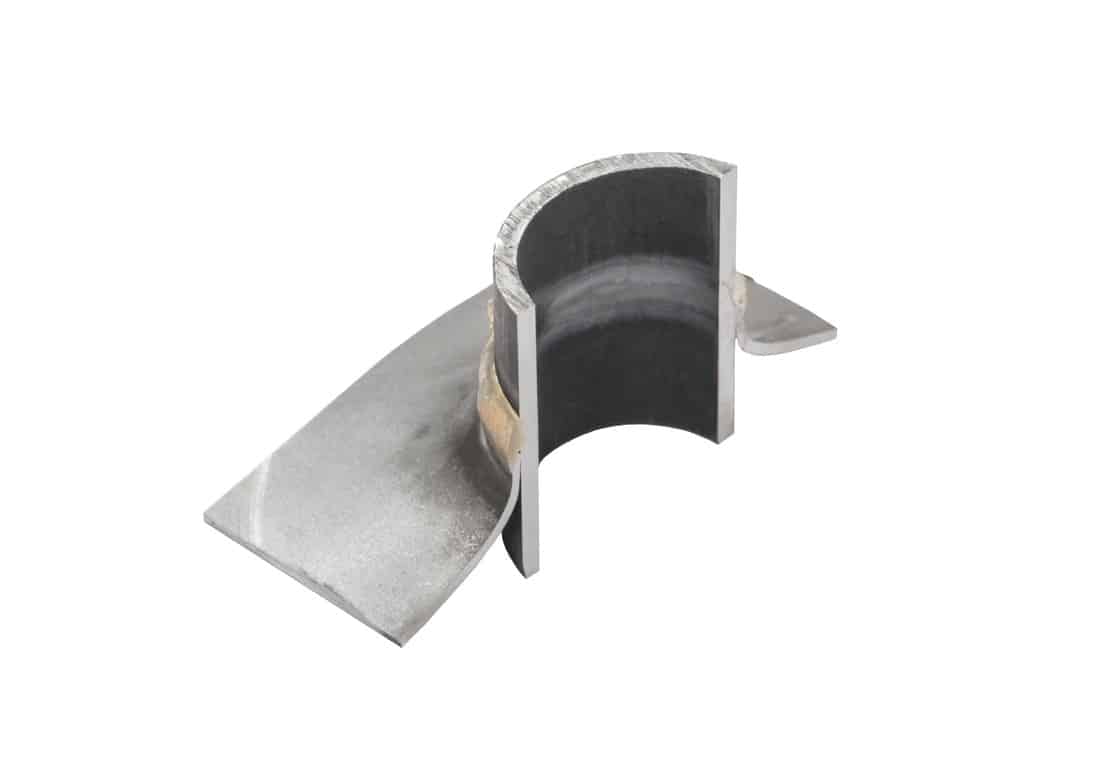

Our Solid State Joining Center is focused on furthering the development of processes that enable the joining of materials at temperatures below their melting point and without the addition of filler metal or shielding gases. Coldwater’s solid state joining solutions include our SpinMeld™ friction spin weld (FSW) machines and SpotMeld™ refill friction stir spot weld (RFSSW) system. Through the Center, Coldwater offer pre-production and low-volume friction spin weld part production on its SpinMeld machines.

The Solid State Joining Center also houses a Materials Evaluation and Testing (MET) lab that provides microstructural evaluation in addition to mechanical testing for weld tensile and hardness verification. This on-site service provides prompt verification of weld integrity, enabling Coldwater Machine to shorten the development time for laser, solid state and arc welding customers.

We accept applications for prototype project requests. Please submit your initial request for parts joining prototype work. We can work to produce custom parts that make use of advanced joining technology as well as apply a joining to your existing parts. Provide some of the information below and we’ll contact you for more details and state the process with your team.